“All human faces are unique”

In the early research we found that masks on the Chinese market where pure industrial masks designed for workers, mainly fitting western males or textile masks for longer use with bad fitting and poor air cleaning as a result. We also identified that there were few competitors, if any, who provided a solution with certified safety requirements of an industrial mask for the general Chinese consumer.

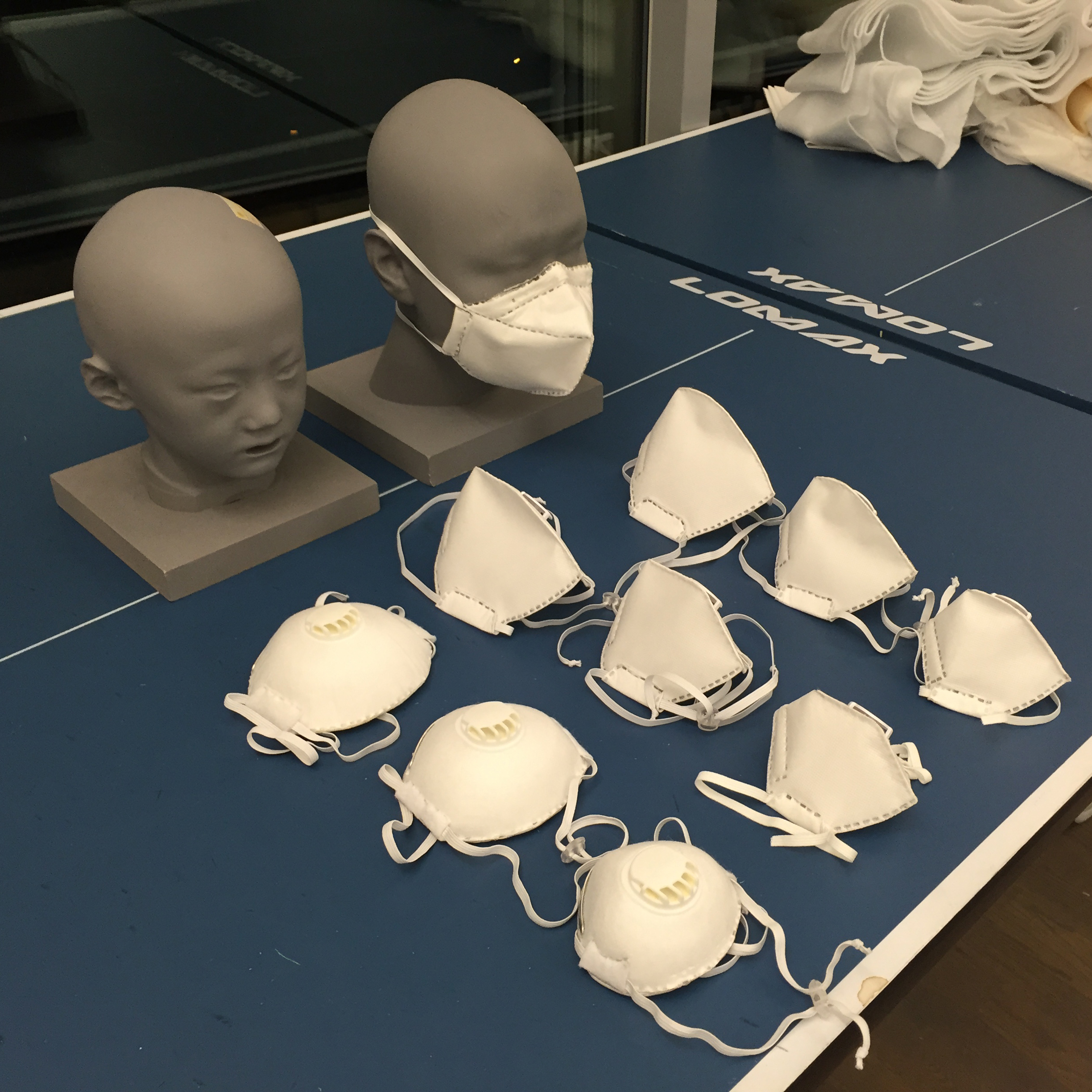

Furthermore, it seemed no-one was doing masks for the entire family. There’s a lack of masks for children who are among the most sensitive groups and no safety standards. On a bad day, conditions can be so severe that the best option can often be to let your children stay home.

Awareness of the outdoor climate and health issues connected to bad air is high, but the difference a good mask can make is not. People do not want to be stigmatized by wearing the mask. It is easier to do what everyone else is doing than to stand out from the crowd. They put their faith in what others are saying, if doctors uses a certain mask and what can be found in reviews. These were important insight for the further development work.

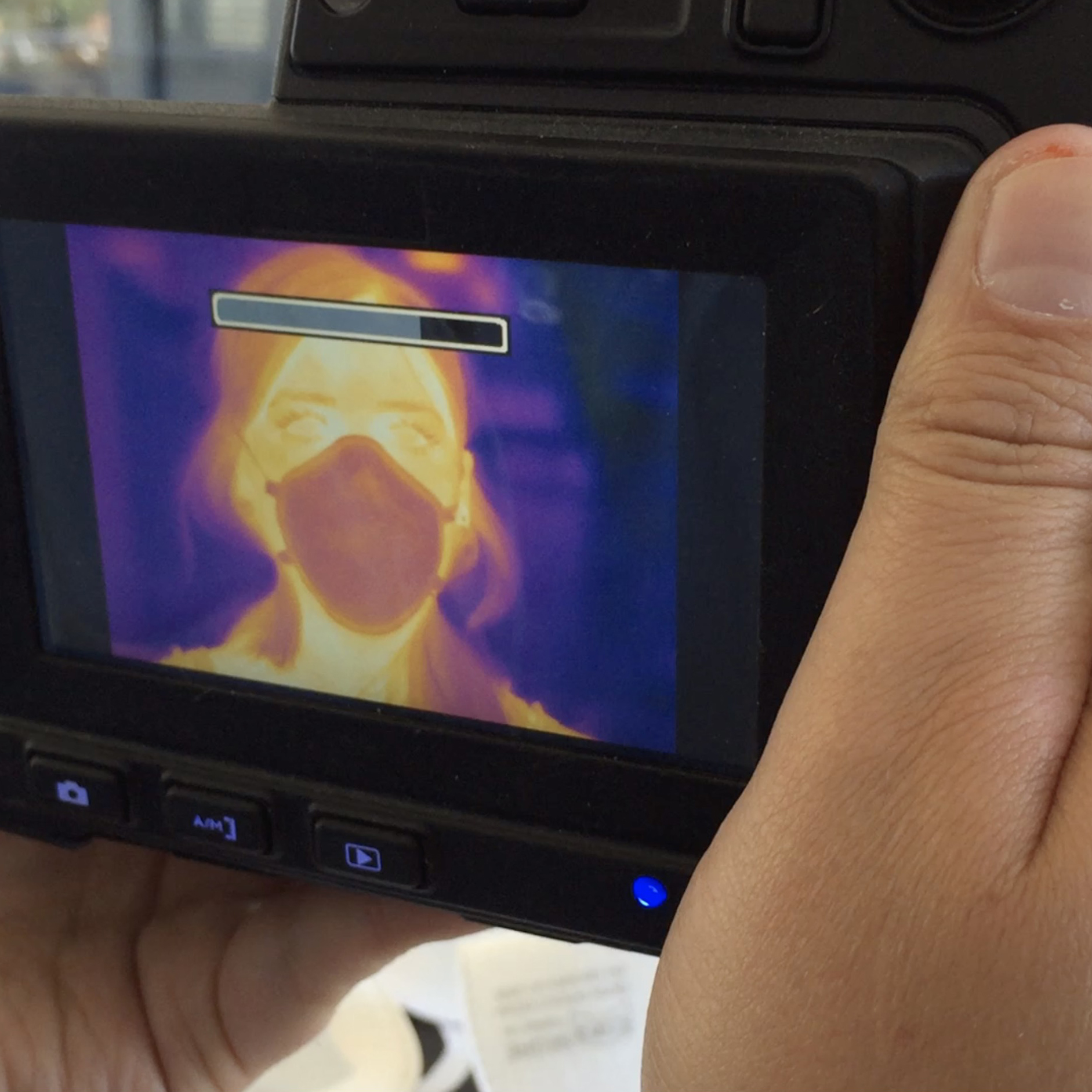

Our approach was to explore what a mask with the industrial safety standards but designed for the life of the mainstream Chinese family could be like. Completely in accordance with the values of the Blueair brand. Looking at their daily activities and problems they are facing by wearing a mask. Things such as, wearing glasses, bicycling to work, exercising, eating and drinking, easy on of removal and communication. A user journey was created to visualize the different activities a person could face during the day.

“Creating the perfect face mask is all about finding the sweet spot between keeping comfort when performing various activities, reducing air leakage and in our case, aligning with manufacturing.”

New form factors, structures, materials and different types of ventilation valves were explored in various prototype builds. Masks integrated with glasses, origami structures that follow the persons jaw when speaking and easily folds together. Ways of making it easier to put on and remove the mask, concepts of covering the masks from getting dirty on the inside etc.

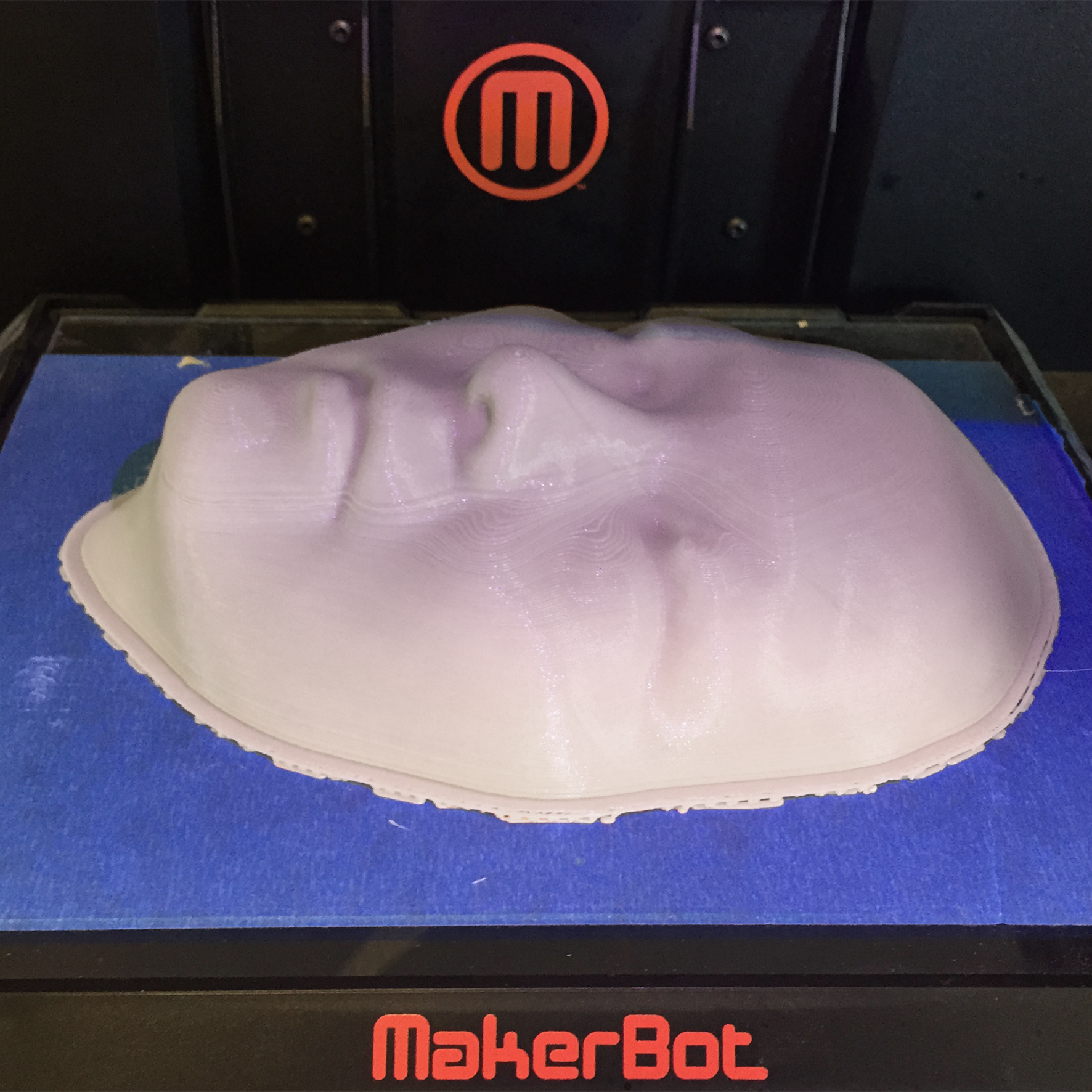

Creating the perfect face mask is all about finding the sweet spot between keeping the comfort when performing various activities, reducing air leakage and in our case, aligning with manufacturing. More than 120 prototypes were hand built in our studio and tested in focus groups both in the Chinese community in Stockholm and later in China.

In parallel to designing and refining product a new production line was developed in close collaboration to an experienced manufacturing partner. The forecasted production volumes were far greater than existing methods of assembly would allow. New methods of production and automation was explored and the team ended up designing an entire production line. By simplifying production steps and challenge approaches to assembly, the production rate was increased by a factor of ten and at the same time keeping the level execution as well as meeting certification standards.